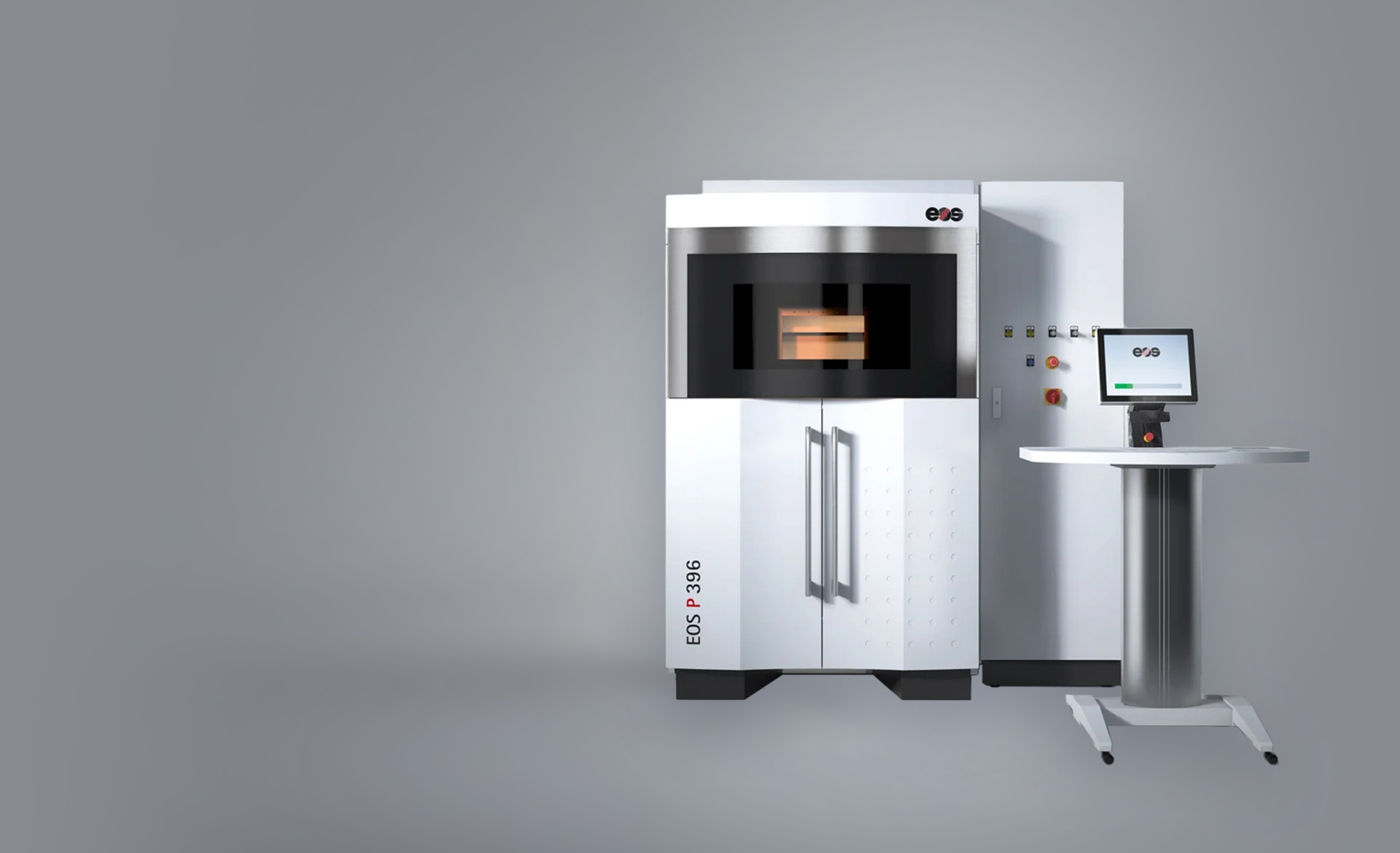

EOS P 396

Integratable into IIoT environments

Build rate of 3 l/h with a packing density of 5%

Widest portfolio of materials on the market

Most homogeneous part properties throughout the entire build volume

Diversity of Materials

14 materials and 26 parameter sets allow a wide range of applications. Requirements of various industries can be completely fulfilled.

Quality of parts

All 3D printed parts with excellent mechanical properties and dimensional accuracy due to software features such as Smart Scaling, EOSAME and a continuous temperature monitoring.

Connectivity

Full integration into the IIoT environment with EOSCONNECT Core resulting in an entirely digital process chain from the CAD model, through ERP and MES connection, to the finished part.

Technické údaje EOS P 396

- Construction Volume

- 340 x 340 x 600 mm (13.4 x 13.4 x 23.6 in)

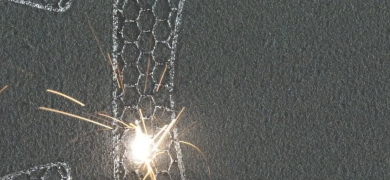

- Laser Type

- CO₂, 70 W

- Precision Optics

- F-theta lens, high-speed scanner

- Scan Speed

- up to 6 m/s (19.7 ft/s)

- Power Supply

- 400 V / 32 A, max. power supply 16 A

- Power Consumption

- typical 2.1 kW; maximum 10 kW

- Machine Dimensions (W x D x H)

- 1,840 x 1,175 x 2,100 mm (72.4 x 46.3 x 82.7 in)

- Recommended Installation Space

- ca. 4.3 x 3.9 x 3.0 m (169.3 x 153.5 x 118.1 in)

- Weight

- ca. 1,060 kg (2,337 lb)

- Software

- PSW 3.8, EOSCONNECT Core, EOSCONNECT MachinePark,EOSCONNECT (open interface OPC-UA, Web API), Smart Scaling

Compatible materials

- PA 1101 - Polyamide 11

- PA 2200 - Polyamide 12

- TPU 1301 - Thermoplastic Elastomer

- PA 1102 Black - Polyamide 11

- HP 11-30 - Polyamide 11

- FR-106 - Polyamide 11

- PA 2201 – Polyamide 12

- PrimePart FR (PA 2241 FR) – Polyamide 12

- PA 2210 FR - Polyamide 12

- PA 3200 GF – Polyamide 12

- Alumide® – Polyamide 12

- PA 640-GSL – Polyamide 12

3D Printing in Practice

3D Printing in Practice

Housings for Electronic Components

Having a stable housing protects the interior. Robust cases are often essential, especially for sensitive electronics. They need to be strong and properly sealed, while also fitting as closely as possible, and they need to be manufactured quickly enough to achieve short production cycles. However, with the injection molding process, manufacturing housings with these properties is only viable in very large series productions.

More information → 3D Printing for Better Insight

3D Printing for Better Insight

Additive Manufacturing of Custom Glasses Frames

Every person’s face is as unique as their personality. To meet the highest fitting standards, glasses frames need to be made to measure. However, they are comparatively expensive to manufacture by hand.

Industrial 3D printing can change this. As an alternative to traditional manufacturing processes, it offers a range of advantages.

3D Printing in Practice

3D Printing in Practice

Additive Manufacturing in Motor Sports

Faster, lighter – and always safe: these are the requirements of motor sports development. For decades, EOS has been working with customers to exploit new potential using industrial 3D printing.

More information →