CeraFab System S65 Medical

The next stage of our CeraFab System S65, specially developed for use in medicine and dentistry.

Innovative patient-specific applications

Outstanding biocompatibility

Effortless mass customization

Here at Lithoz, we strive to provide the medical and dental fields with only the highest quality of technology and services. Our new CeraFab System S65 Medical facilitates the production of top quality 3D-printed components, possessing outstanding biocompatible properties and offering near-limitless geometries. From patient-specific implants to mass customization, from medical to dental applications - imagination is the only limit. State-of-the-art CeraDoc software allows for the simple and automatic documentation of medical device production, ensuring complete traceability and easy data analysis. The tool-free LCM technology means CAD data can be modified to match specific patient needs , while our bioceramic materials are the top choice for medical and dental applications.

CeraFab System S65 Medical

- Lateral resolution

- 40 µm

- Build envelope

- 102 × 64 × 320 mm

- Slice thickness

- 10 – 100 µm

- Number of pixels (X, Y)

- 2560 × 1600 - WQXGA

- Data format

- .stl

- Build speed

- Up to 150 layers per hour

- Size (L× W ×H)

- 1 production cell incl. a control unit (L × W × H): 1.05 × 0.85 × 1.78 m

- Weight

- ca. 400 kg

Additive Manufacturing for Dental Medicine

Additive Manufacturing for Dental Medicine

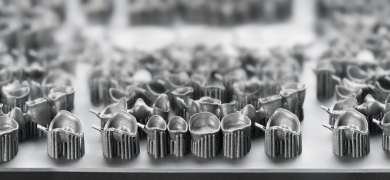

3D Printing of Bridges, Crowns and More

Partial dentures need to fit the patient without any compromise, as well as looking natural and aesthetic. Ideally, they should also last forever. Bridges, crowns and model cast prostheses are usually manufactured by hand – a complex and cost-intensive process.

More information → 3D Printing in Practice

3D Printing in Practice

Additive Manufacturing for Serially Produced Vehicles

We help our customers implement additive manufacturing wherever it can fully demonstrate its strengths. This ranges from major changes to logistics systems, detailed equipment customization and lightweight parts, to engine technology fine-tuning. 3D printing technology holds the potential to optimize the automotive production value chain and react quickly and flexibly to new trends. This potential is extremely valuable in an industry where every player, automotive manufacturer, OEM and tooling provider faces high costs and innovation pressure.

More information → 3D Printing in Practice

3D Printing in Practice

Additive Manufacturing in Motor Sports

Faster, lighter – and always safe: these are the requirements of motor sports development. For decades, EOS has been working with customers to exploit new potential using industrial 3D printing.

More information →