CeraFab System S25

Industry-leading and trusted 3D printers, designed for scalability and ready for advanced developments and serial production.

Boosted productivity

Unmatched precision

Consolidated reliability

The CeraFab System family is the ultimate choice for enabling the industrial serial production of high-performance ceramics using additive manufacturing. Each machine in the CeraFab System family, consisting of the S25, S65 and S230, offers a full 3D printing system for advanced developments. A total of four production units can be combined, making it easy to scale-up and enabling the rapid manufacture of exceptional ceramic components. From small-scale to large part production, these machines can accommodate all types of high-quality 3D printing projects thanks to their different build volumes and have the fastest building speed on the market. The current generation of projectors with WQXGA resolution, in combination with an objective lens specially developed for the process, ensures the absolute precision of printed components – even in the micrometer range.

CeraFab System S25

- Lateral resolution

- 25 µm

- Build envelope

- 64 × 40 × 320 mm

- Slice thickness

- 10 – 100 µm

- Number of pixels (X, Y)

- 2560 × 1600 - WQXGA

- Data format

- .stl

- Build speed

- Up to 150 layers per hour

- Size (L× W ×H)

- 1 production cell incl. a control unit (L × W × H): 1.05 × 0.85 × 1.78 m

- Weight

- ca. 400 kg

3D Printing in Practice

3D Printing in Practice

Additive Manufacturing for Serially Produced Vehicles

We help our customers implement additive manufacturing wherever it can fully demonstrate its strengths. This ranges from major changes to logistics systems, detailed equipment customization and lightweight parts, to engine technology fine-tuning. 3D printing technology holds the potential to optimize the automotive production value chain and react quickly and flexibly to new trends. This potential is extremely valuable in an industry where every player, automotive manufacturer, OEM and tooling provider faces high costs and innovation pressure.

More information → Additive Manufacturing for Dental Medicine

Additive Manufacturing for Dental Medicine

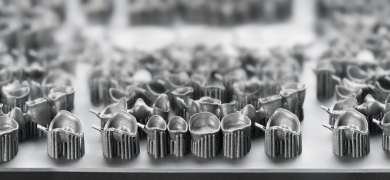

3D Printing of Bridges, Crowns and More

Partial dentures need to fit the patient without any compromise, as well as looking natural and aesthetic. Ideally, they should also last forever. Bridges, crowns and model cast prostheses are usually manufactured by hand – a complex and cost-intensive process.

More information → 3D Printing in Practice

3D Printing in Practice

Additive Manufacturing in Motor Sports

Faster, lighter – and always safe: these are the requirements of motor sports development. For decades, EOS has been working with customers to exploit new potential using industrial 3D printing.

More information →